On outboard-powered vessels, it’s critical to keep debris off the prop while also performing other essential maintenance. Otherwise, you risk getting a faulty outboard lower unit. So are you facing Yamaha outboard lower unit problems?

Shifting problems may result from defective outboard lower components. Other signs include magnetic particles on the outflow screw magnet. It can also show clunking sounds when shifting. It may even show the inability to shift into gears. After identifying the problem you can solve them.

This article will give us more information on it.

Table of Contents

ToggleWhat Is an Outboard Motor’s Lower Unit?

An outboard motor’s lower unit, also known as the gear case, is the section of the motor that sits below the waterline and houses the propeller, driveshaft, gears, and other components that transmit power from the motor to the water.

The lower unit is responsible for converting the high-speed, low-torque output of the motor into the low-speed, high-torque rotation required to turn the propeller and move the boat through the water.

The lower unit is typically sealed with a gasket or o-ring and filled with lubricating oil or grease to reduce friction and wear on the moving parts.

It may also have a water pump or impeller that circulates water through the motor to keep it cool.

The lower unit can be damaged by impact with underwater obstacles, exposure to abrasive or corrosive materials, or overheating due to insufficient lubrication or water flow.

Regular maintenance, including oil changes, lubrication, and inspection for damage or wear, can help prevent costly repairs and extend the life of the moto

How Does a Lower Unit Function?

The gearcase is another name for the lower component. It is part of the outboard motor. This is the powerhead of the engine. It is attached in order to transmit rotation and power to the propeller.

Your boat can propel itself forward or reverse through the water because the propeller revolves.

If a component of the lower unit malfunctions or fails, you may become stranded in the water.

How Can I Tell If My Outboard Lower Unit Is Faulty?

A faulty outboard lower unit can cause a variety of problems, but the hereunder are the most frequent issues. Let’s look at them.

Water in Gear Case Lubricant

As previously stated, the presence of water in the gearbox lube indicates a problem. When replacing the lubrication, you can search for warning indicators of danger.

Before the water in the gear, the lube causes the lower unit to fail. The switch rod linkage or the linkage designed to connect to the handle enables the operator to manually process and change gears.

This may be to blame if the outboard motor drifts out of gear. Any broken or damaged elements in the upper or lower shift rod linkage, such as the bearing surfaces or coupler, should be supplemented.

Solution

It is crucial to replace your gear grease every 100 hours for this reason. By doing so, you can identify the issue and stop the leak.

Metal Contamination in the Gear Case Drain Screw Magnet

Never let the metal particles on your lower magnetic gearbox drain screw magnet exceed 3/4″. Mash any contaminants in your hands while inspecting the magnet.

If it becomes a gray powder, you can fully discard it. Otherwise, you should be concerned if you feel metal during the process. The magnet almost always has a small quantity of metal on it.

It is only when the metal buildup becomes significant that you should be concerned and begin the process of determining what is wrong with the lower unit.

Solution

Start by removing the drain plug with a screwdriver. Some outboards may entail an equipment includes, that also decreases the risk of stripping threads.

Because the lower unit cords are magnetic, you may notice some metal shavings that indicate wear. Nothing to be concerned about if you merely see a few, but an excessive number should be.

Clanking Noises

If you begin to hear repeated clanking noises, it can be the gear or axles. When a tooth falls out, it makes this annoying sound. And at the appropriate RPM, it will become lodged between the gears and blow up the lower unit.

When you attempt to operate your outboard in forward or reverse, you hear a few crunching. But the unit engages. While the sound may be coming from your lower unit, the issue may not.

The clutch dog, which is circled in the image above, gets involved to enable the outboard to run forward or reverse. You’ll hear grinding if the engagement isn’t smooth.

This noise may indicate that you need to modify your throttle cable so that the shift is finished before applying the throttle and increasing RPMs.

Solution

You can oil up the engine if there is a sound. Check out the connection and make sure they are in the proper place.

Milky Oil

A milky or whitish tint in the outboard motor lower unit gear oil implies a water leak, which can also cause the engine to stall or fail. A broken propeller seal is frequently the cause of outboard engine lower unit leaks.

Solution

To solve the problem, the controller should substitute the protective layer and flush the oil.

Your oil must not be milky, but rather dark. If it appears milky, it is most likely because of polluted water by a leaking seal or debris. You need to choose the correct oil for your lower unit.

Instead of simply changing the oil, address the underlying issue. Alternatively, water would then proceed to permeate into the oil, causing the gearbox to fail.

Examine the head gasket on the oil plugs as well. It’s better to upgrade them if they’re worn or frayed. If your gasket separates from the plug and remains in the hole, it’s time to switch out the entire plug.

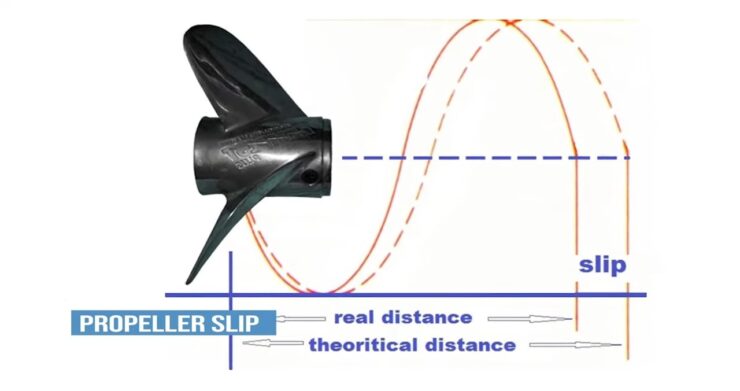

Propeller Slippage

If the lower unit propeller of an outboard engine sustains damage,it can slide down on its hub and cause impeded outboard steering. Especially, which is often induced by hitting or trying to push against a submerged blockage.

Check for damage and replacing either the wheel or the propeller as necessary.

Solution

Position the outboard vertically. The propeller should be parallel to the pavement at all times. If the sewage turtles are in the lower unit’s back.

If they are located on this same bottom of the gearcase’s nose. Then, lean the engine or lower unit up so that the drain screw is in the bottom rank on the gear case.

Place cardboard on the ground beneath the motor. Put the oil pan beneath the prop. It also depends on the lower unit compatibility.

Distancing the Lower Unit from the Powerhead

It is critical to re-grease splines when reinstalling a lower unit. If you’re attempting to pull a lower unit, that ship has sailed.

The best advice is to gently pry apart the lower unit housing from the powerhead. You can pry the metal against the scrapers with a screwdriver after separating it using thin metal scrapers.

This will safeguard the mating surfaces of the powerhead and lower unit.

Lower Unit Rebuild Costs

You have several options if your outboard lower unit fails. The option to replace the unit or rebuild it is available.

If you are mechanically inclined, rebuilding the lower unit would be far less expensive than purchasing a new one. However, this will take more time from you than simply making a purchase.

You must decide which is preferable in your situation.

Thus you solve your Yamaha outboard lower unit problems.

FAQs

Is it possible to run an outboard motor without the lower unit?

No, it is not possible to run an outboard motor without the lower unit. The lower unit is an essential part of the motor’s propulsion system, responsible for transmitting power from the motor to the water through the propeller.

Without the lower unit, there would be no way to turn the propeller and generate thrust, and the motor would not be able to move the boat through the water.

Attempting to run an outboard motor without the lower unit could cause serious damage to the motor, as well as the boat and anyone on board.

The exposed driveshaft and gears could be damaged by debris in the water or by running the motor dry, which could result in costly repairs or even total motor failure.

How often should your outboard lower unit’s oil be changed?

The recommended interval for changing the oil in an outboard motor’s lower unit varies depending on the manufacturer and model, as well as the operating conditions and usage of the motor. In general, it is recommended to change the lower unit oil every 100 hours of use or at least once a year, whichever comes first.

However, if the motor is operated in harsh conditions, such as saltwater or polluted water, it may be necessary to change the lower unit oil more frequently, as these conditions can accelerate wear and corrosion of the lower unit components.

It is also a good practice to inspect the lower unit oil periodically for signs of contamination, such as metal particles, water, or discoloration, which could indicate damage or wear to the lower unit. If any of these conditions are present, the lower unit oil should be changed immediately, and the motor should be inspected for damage or wear.

What is the weight of Yamaha’s lower unit oil?

The weight of Yamaha’s lower unit oil, also known as gearcase lubricant, depends on the specific model of the outboard motor and the operating conditions. Yamaha offers a range of gearcase lubricants with different viscosities and properties to meet the requirements of different applications.

For example, Yamaha’s Yamalube 2M is a high-performance, mineral-based lubricant that is designed for use in two-stroke outboard motors. It has a weight of SAE 80W-90 and is recommended for use in temperatures above 20°F (-6°C).

Yamaha’s Yamalube 4M is a synthetic blend lubricant that is designed for use in four-stroke outboard motors. It has a weight of SAE 10W-30 and is recommended for use in temperatures above 40°F (4°C).

How much does it cost to rebuild an outboard lower unit?

The cost to rebuild an outboard lower unit can vary widely depending on several factors, including the make and model of the outboard motor, the extent of the damage or wear to the lower unit components, and the cost of parts and labor in the local area.

A basic lower unit rebuild can cost between $300 to $500, while a more extensive rebuild that requires replacement of major components such as gears or bearings can cost between $1000 to $1500 or more.

The cost of parts, such as seals, gaskets, and bearings, can also add up quickly and can range from $100 to $500 or more.

It is important to have the outboard motor and lower unit inspected by a qualified technician before committing to a rebuild, as some damage or wear may not be visible or may be indicative of more serious issues.

In some cases, it may be more cost-effective to replace the entire lower unit rather than rebuild it.

Conclusion

I hope you have learnt all about Yamaha lower unit problems. This article should assist you in troubleshooting your outboard lower unit issues.

We want to assist you in keeping your boat operating smoothly and efficiently.

That’s all for today!

I’m Liam Jackson, the proud owner and driving force behind KayakPaddling.net. Born somewhere in the expansive beauty of the United States, I’ve nurtured a lifelong passion for kayaking and fishing that has led me to explore the far corners of our nation’s waterways.

Related Posts:

- 16 Best Kayak For Beginners 2024 - Kayaking Adventure Gear

- 12 Best Beach Wagons & Carts 2024 - For All-Terrain

- 10 Best Fish Finders Under $200 2024 - Top Affordable Picks

- 11 Best Prop for Yamaha F70 in 2024: Choose The Best

- How to Stay Safe on Slow Moving Waters When Paddle Boarding?

- 13 Best Fishing Kayak Under $500 in 2024 -…