When installing a trolling motor, it is strongly advised to use a circuit breaker or fuse. With this breaker installed, power will be cut off when the power draw reaches 50 amp, preventing motor damage.

This breaker is designed for motors that draw less than 60 amps during normal operation, but it can also be used with other motors.

So, how to install a 50 amp circuit breaker for the trolling motor?

This circuit breaker is simple to install between the battery and the motor. This breaker comes with 6″ of cable for connecting to the battery and 4 feet of cable for connecting to the trolling motor or power lead. The linking of the wire to the circuit breaker will be determined by the terminal.

The influence of circuit breakers for the battery powered trolling motor will be discussed in this article. And how to put them in. Let’s begin.

Table of Contents

ToggleWhat Exactly is a Circuit Breaker, and How does it Function?

A circuit breaker is an electrical safety device designed to protect an electrical circuit from damage caused by overloading or short circuits.

It functions by interrupting the flow of electrical current when the circuit becomes overloaded or a short circuit occurs, which can cause the wires and electrical components to heat up and potentially catch fire.

It consists of a switch mechanism that is triggered by an electrical current overload, and a thermal or magnetic trip mechanism that causes the switch to open and interrupt the circuit.

The thermal trip mechanism is activated by an increase in temperature caused by an overload, while the magnetic trip mechanism is activated by a sudden surge in current caused by a short circuit.

When the circuit breaker is in the “on” position, the switch allows current to flow through the circuit.

If the current exceeds the rated limit of the circuit breaker, the trip mechanism is activated and the switch is opened, interrupting the flow of current.

This protects the circuit from damage and prevents electrical fires.

Need a Circuit Breaker for Your Electric Trolling Motor?

Although they might seem tiny, circuit breakers are crucial to the functionality of your electric trolling motor. They safeguard the motor’s internal electrical system as well as the wiring on your boat. Trolling motors are frequently overloaded.

They are also vulnerable to short-circuit damage. This is prevented by circuit breakers. The circuit breaker will experience an electrical spike beforehand if your trolling motor experiences a heavy load or short circuit.

It will crash or shut down as a consequence. Troilling motor can cause other problems also.

Once your propeller or trolling motor encounters additional resistance, an electrical surge occurs. This can occur if the propeller becomes entangled in weeds or becomes stuck among rocks.

Because the motor must function at the required frequency, more power is drawn in to overcome the resistance.

This rise in the electrical current can occasionally cause a short circuit. This can cause significant damage to many important components of the motor if the circuit breaker is not in place.

Aside from some external forces, the circuit may encounter resistance if:

- A long wire connects the power source and the device.

- The wire diameter is insufficient.

- The wire’s material and the number of strands

- Any corroded or loose electrical circuit connections

If you’re wondering whether or not you should install a circuit breaker in your trolling motor, the answer is yes. Moreover, your trolling motor can lose power.

In bigger vessels, any conductor current – carrying wire that is not insulated needs to be protected by a circuit breaker or fuse.

The Various Types of Circuit Breakers

There are various types. Normally, the power of the trolling motor that is placed in your boat determines what kind of fuse box you need. You can install a trolling motor circuit breaker, for instance, if the highest electricity your trolling engine can handle is 50 amps.

The following are some distinctive aspects to take into account before buying a circuit breaker for your motor:

- The thrust or model of the motor

- Your motor’s maximum ampere draw

- The capacity of the VDC

- The wire extension’s length

50 Amp Circuit Breaker for Trolling Motor

There can be different types of circuit breakers for 50 amps. These are some examples:

- 50 Amp Circuit Breaker (12 VDC) – This circuit breaker can handle trolling motors that weigh 30, 40, and 45 pounds. These motors have maximum amperage draws of 30 and 42 amps, respectively.

- 50 amp circuit breaker (24-volt direct current) – This circuit breaker is suitable for a 70-pound trolling motor. This motor’s maximum ampere draw is 42 amps.

- 50 amp circuit breaker (36-volt direct current) – This circuit breaker is suitable for a 101-pound trolling motor. This motor’s maximum ampere draw is 46 amps.

- 50 amp circuit breaker (48-volt direct current) – This circuit breaker is suitable for an E-Drive motor. These motors have a maximum ampere draw of 40 amps.

The aforementioned circuit breakers can adequately protect your trolling motors if the essential requirements are met.

The voltage loss shouldn’t be greater than 5% when the motor is operating at full capacity.

How to Install a Trolling Motor Circuit Breaker

A circuit breaker for your trolling motor can be installed by a marine technician. However, if you want to do the job yourself, here are some guidelines to help you:

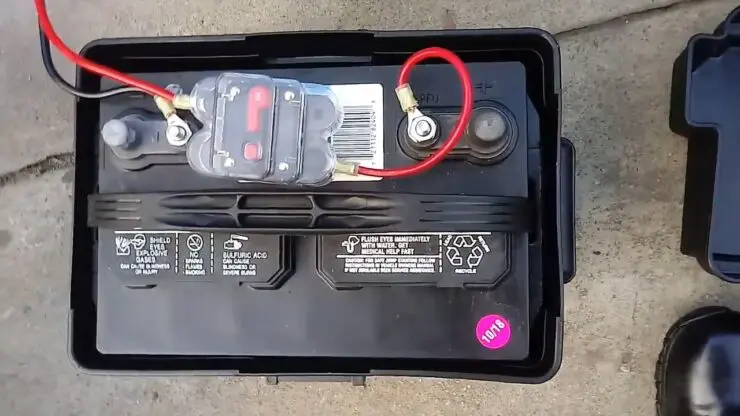

Select a suitable location in your boat for mounting the circuit breaker. It is preferable to locate the breaker near the battery or batteries.

Utilize the two holes at the base of the circuit breaker to mount it.

- Link the “BAT” terminal on the breaker towards the positive conclusion of something like the battery post.

- Locate the POSITIVE wire that connects your electric trolling motor to your marine battery.

- Prepare an extra battery cable or cut the cable where you want to install the circuit breaker. It should be located just next to the battery, not over 1.8m away. If you snip the cable, you will have to connect wire terminal ends in order to connect it.

- There will be two terminals on the circuit breaker. They may be labeled BAT (power pack) and AUX (motor), IN (power supply) and OUT (motor), or not labeled at all. This is irrelevant because electricity flows through both methods, so you can’t accidentally switch the terminals.

- The AUX and BAT terminals on the circuit breaker will be labeled. One will be connected to the trolling motor, while the other to the battery.

- Hook up the trolling motor’s positive power cord to the terminal labeled “AUX” on the breaker.

The technique of attaching the cut wire to the terminals of the circuit breaker will be determined by the terminal itself.

Additional Guidelines for Buying a Circuit Breaker

When purchasing a circuit breaker for your trolling motor, keep the following in mind to ensure adequate circuit protection:

- Choose a trip-free circuit breaker that can be manually reset.

- The circuit breaker must be capable of interrupting enough amps.

- The circuit breaker should continue to function after just a short circuit or the other electrical malfunction.

- In some cases, a fuse should be installed before the circuit breaker. This may boost the circuit breaker’s ability to disrupt amps.

- Check the circuit breaker for ignition protection. This is done by running an electrical test while applying four times the breaker’s current rating.

- Seal the positive terminal(s) of the battery(s) with electrical tape or a shielding to avoid short circuits. This can prevent it from getting into contact with anything that might lead to a malfunction. Such as metal objects, errant wiring, or other things.

You need to choose the correct circuit breaker and wiring for installation on your motor.

Things You Need to Know

Circuit breakers are critical components of your electric trolling motor’s circuit protection.The trolling motor may get damaged if a circuit breaker isn’t used.

If a fire starts as a response of an overheat or short circuit, you might be at risk.

FAQs

How many amps does a trolling motor breaker require?

Overall, if the trolling motor weighs between 30 and 45 pounds, a 50-amp breaker is preferable. Those weighing 50 to 55 pounds are more likely to succeed when paired with a 60-amp one.

What wire gauge is required for a trolling motor?

We recommend using #10 AWG 105C wire when extending the cables of your trolling motor up to 94″. (for 55lb Thrust Trolling Motors and smaller). If you need to extend the cables beyond 94″, we recommend #8 AWG 105C.

Is a circuit breaker required for a winch?

It is not advisable to use a circuit breaker or a fuse. Your winch can consume 400 amps. A single battery can only supply 700 amps for a limited time. A fuse or circuit breaker too big to allow your winch to function cannot protect anything.

Do trolling motors need a circuit breaker?

Yes, trolling motors typically require a circuit breaker to protect the motor and wiring from electrical overload. The circuit breaker acts as a safety device, automatically interrupting the flow of electricity if the motor draws too much current or if a short circuit occurs.

Without a circuit breaker, the motor and wiring could be damaged or even catch fire in the event of an electrical fault.

The appropriate size and type of circuit breaker will depend on the motor’s amperage rating and the wiring size and length, and should be installed according to the manufacturer’s instructions.

What size wire should be used for a trolling motor?

The size of wire that should be used for a trolling motor depends on the motor’s amperage rating and the length of the wire run. As a general rule, heavier wire (with a lower gauge number) should be used for higher amperage motors and longer wire runs.

A 12-volt trolling motor with a maximum amperage draw of 50 amps, for example, should use wire that is at least 6-gauge for a wire run up to 12 feet, or 4-gauge for a wire run up to 22 feet.

For a 24-volt trolling motor with a maximum amperage draw of 70 amps, wire that is at least 4-gauge should be used for a wire run up to 8 feet, or 2-gauge for a wire run up to 16 feet.

It’s important to refer to the manufacturer’s specifications and guidelines to ensure that the correct wire size is used for the specific motor and application.

Can I use a fuse instead of a circuit breaker, and what is the size recommendation?

While a fuse can provide protection for a trolling motor, it is generally not recommended as a primary form of protection, as fuses can be more difficult to replace and reset than circuit breakers.

Circuit breakers are designed to automatically interrupt the flow of current when an overload or short circuit occurs, and can be reset simply by turning them off and then on again.

Fuses, on the other hand, must be physically replaced when they blow.

If a fuse is used as the primary protection for a trolling motor, it should be appropriately sized for the motor’s amperage rating and the wiring size and length.

As a general rule, the fuse should be sized to allow for the maximum amperage draw of the motor, plus a safety margin of 25% to 50%.

For a 12-volt trolling motor with a maximum amperage draw of 50 amps, for example, a 60-amp or 70-amp fuse could be used.

For a 24-volt trolling motor with a maximum amperage draw of 70 amps, a 90-amp or 100-amp fuse could be used.

It’s important to refer to the manufacturer’s specifications and guidelines to ensure that the correct fuse size is used for the specific motor and application.

Conclusion

I hope you have learned all about how to install a 50-amp circuit breaker for the trolling motor.

Installing an electric trolling motor is a simple task if you read the installation manual. consult the USCG code page, and plan ahead of time.

Thank you for reading.

I’m Liam Jackson, the proud owner and driving force behind KayakPaddling.net. Born somewhere in the expansive beauty of the United States, I’ve nurtured a lifelong passion for kayaking and fishing that has led me to explore the far corners of our nation’s waterways.

Related Posts:

- Where is the Fuse Box on a Boat? - Helps in Powering…

- Heavy Duty Fishing: 11 Best Rods And Reels For Big Fish 2024

- 10 Best Inflatable Kayak 2024 - Rivers, Lakes & Open Seas

- 10 Best Trolling Motors For Kayaks 2024: Motorizing…

- 12 Best Motorized Kayak 2024 - Start Your Aquatic Adventure!

- 10 Best Saltwater Fishing Boats - Ultimate Angling Adventure